Understanding Laser Levels: Types and Applications

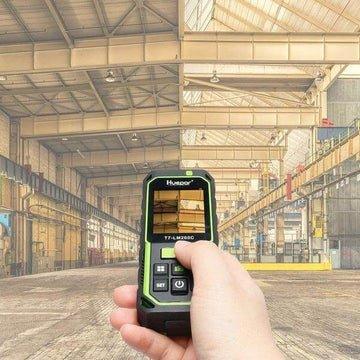

The Basics of Laser Levels

Laser levels are tools for precision alignment in construction and DIY projects. They emit a straight line beam to ensure levelness or plumb on a surface. There are various types, each with unique features. You'll find dot lasers, line lasers, and rotary lasers. Dot lasers project single points on a surface. Line lasers emit horizontal and vertical lines. Rotary lasers cast a 360-degree line around a room. Each type suits different tasks. They help in hanging pictures, tiling walls, and laying pipes. Safety is key—never aim the beam at your eyes.

Comparing 3D, Cross Line, and 4D Laser Levels

When selecting a laser level, understanding the differences between 3D, Cross Line, and 4D laser levels is crucial. Here's a simple comparison:

- 3D Laser Levels: These provide 360-degree coverage, projecting lines on all walls, floors, and ceilings simultaneously. They're ideal for complex layouts and full-room installations.

- Cross Line Laser Levels: Perfect for tasks such as hanging pictures or installing cabinets, these emit cross pattern lines on one or two wall surfaces at a time.

- 4D Laser Levels: A step up from 3D, the 4D models add an additional plane, offering more reference points. They are best for jobs requiring the highest precision.

Each type has its unique applications and choosing the right one depends on the complexity and precision required for your project.

Common Applications for Different Types of Laser Levels

Different types of laser levels suit various projects. Here's how they are commonly used:

- 3D Laser Levels: These are perfect for tasks requiring precise cube reference points. They suit indoor work like aligning wall tiles or cabinetry and outdoor jobs like landscaping.

- Cross Line Laser Levels: Ideal for hanging pictures, installing drop ceilings, and other alignment tasks, these levels project horizontal and vertical lines simultaneously.

- 4D Laser Levels: These advanced tools are used for complex layouts. They are often used in construction sites where full-room level, align, or square references are needed.

Selecting the Right 3D Laser Level for Your Project

Key Features to Consider

When choosing a 3D laser level, consider several key features:

- Accuracy: Look for levels with high precision. Check the accuracy specs.

- Range: The working range should fit your project's needs. Longer for big sites.

- Durability: Pick a robust device. It should withstand tough job conditions.

- Self-Leveling: This feature ensures the level auto-adjusts to align perfectly.

- Battery Life: Longer battery life means less downtime on your project.

- Mounting Options: Ensure it has versatile mounting for various surfaces and angles.

- Visibility: A bright laser is vital for clear visibility, even in daylight.

- Additional Features: Some levels come with remote control or Bluetooth for ease.

- Price: Balance the features with your budget. Don't overpay for unneeded extras.

- Warranty: A good warranty protects your investment in the tool.

These features will help you pick the best 3D laser level for your work.

Top Brands and Models in the Market

When choosing a 3D laser level, the vast array of brands and models can be overwhelming. Here are some top picks:

- DeWalt: Known for robust construction tools, DeWalt offers 3D laser levels that are durable and easy to use.

- Bosch: Bosch laser levels are renowned for precision and quality, with features suited for both professionals and DIY enthusiasts.

- Spectra Precision: Spectra's laser levels are top-of-the-line, ideal for complex projects requiring high accuracy.

- Hilti: Hilti's laser levels provide innovative technology and superior performance, perfect for demanding tasks.

Each of these brands brings something different to the table, and selecting the best one depends on your project needs, budget, and the level of precision required. It's important to compare the specific features and benefits of each model before making your decision.

Tips for Setting Up and Using Your 3D Laser Level

When setting up your 3D laser level, follow these simple tips:

- Ensure the device is on a stable surface to avoid movement.

- Calibrate the laser level according to the manufacturer's guidelines.

- Check the battery life before starting, to avoid interruptions.

- Use the self-leveling feature, if available, for accurate results.

- For outdoor use, choose a time with minimal sunlight to see the laser better.

- Align the laser with your reference points before beginning your project.

- Secure the laser level firmly if attaching to a tripod or wall mount.

- Always double-check your measurements for precision.

By following these steps, you can improve the accuracy of your work and extend the life of your 3D laser level.

Enhancing Your Skills: Best Practices and Maintenance

Troubleshooting Common Issues

When working with 3d laser levels, encountering technical issues can halt your project. Identifying and fixing common problems ensures tools perform well. This section helps troubleshoot issues you may face. It covers alignment errors, power malfunctions, and accuracy problems. Here's a list of potential issues and how to resolve them:

- Alignment Problems: Verify your laser level is on a flat surface. Adjust the self-leveling feature as needed.

- Power Issues: Ensure batteries are charged or replace if needed. Check for any loose connections.

- Beam Visibility: Clean the laser diode carefully. If the problem persists, consider a laser detector.

- Accuracy Concerns: Recalibrate your device regularly. Follow the manufacturer's instructions.

By knowing these quick fixes, you can save time and maintain precision on-site. Remember, preventing issues is just as important as solving them. Regularly caring for your tool reduces the risk of these problems.

Maintenance and Care Tips for Laser Levels

Proper maintenance extends the life and accuracy of your 3D laser level. Here are key care tips:

- Keep the device clean, wiping it gently with a soft cloth to remove dust.

- Store it in a protective case to ward off damages from impacts or moisture.

- Check calibration regularly to ensure ongoing precision, following the manufacturer's instructions.

- Avoid exposing it to extreme temperatures which can damage the laser components.

- Handle the battery with care, recharging it as needed and replacing it in accordance with the guidelines.

- Inspect the laser level before use to identify any potential issues.

With these simple care routines, your 3D laser level will remain a reliable tool for any project.

Advanced Techniques for Precision Measuring with 3D Laser Levels

Excel in precision measuring with 3d laser levels using these advanced techniques.

- Ensure the level is on a stable surface to avoid errors.

- Use the plumb line feature to achieve vertical accuracy.

- For large spaces, utilize multiple reference points to maintain consistency.

- Master the receiver's use to detect laser lines over long distances or in bright conditions.

- Regularly check the device's calibration for reliable results.

- Experiment with different mounting options for optimal versatility.

- Practice makes perfect. Spend time getting to know your laser level's specific features.